Indoor LED Display Module

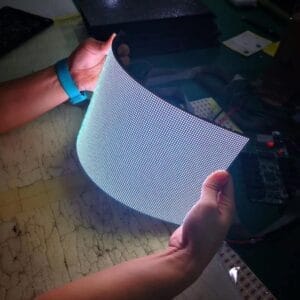

High Refresh Rate to 3840HZ indoor LED Screen Panel, High-quality full-color SMD indoor LED display module Including the Data Power Cables and 2 Years Warranty, All LED modules With Best Contrast and Color uniformity to ensure the LED display has an excellent visual effect.

3840Hz Refresh Rate

SMD LED

2 Years Warranty

Indoor LED Screen Panel

LED Lamp

For the Indoor LED display module, we choose Kinglight and Nationstar LED which have high reliability and contrast, wide view angle, and good consistency which meet the need for high brightness, high refresh rate,high gray scale, and keep natural color at one time with best color uniformity.

Driver IC

To achieve the best visual performance of our indoor and outdoor led display, we use the best Driving IC, such as MBI5124, MBI5153, ICN2038S, and ICN2153 with high refresh rate, high grey level with the latest technology.

72 Hours Aging Test

72 hours aging test (white balance aging (2×24 hours) and video aging (24 hours)) to improve the reliability of the indoor LED display modules and ensure the LED modules are without broken LEDs.

All Pixels Available

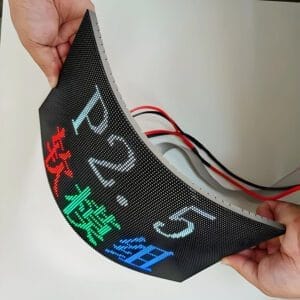

LED-City Indoor LED display Panel has all pixel available from P2mm, P2.5mm, P3mm, P3.91mm, P4mm, P4.81mm, P5mm, P6mm, P6.72mm, P10mm and small pixel series such as P1.875mm , P1.25mm, P1.538mm, P1.667mm, P1.86mm, etc

Contact Us

320*160mm

High Refresh Rate

SMD 3 in 1

2 Years Warranty

CE,RoHS,FCC Approved

320X160mm Series

| Pixel Pitch | LED | Module Resolution | LED Type | Brightness(Nits) | Module Size(MM) | Driving Mode |

| P1.25mm | 1010 (Black LED) | 256*128 | SMD 3in1 | 600-800 | 320*160 | 1/64Scan |

| P1.538mm | 1010 (Black LED) | 208*104 | SMD 3in1 | 600-800 | 320*160 | 1/52Scan |

| P1.667mm | 1010 (Black LED) | 192*96 | SMD 3in1 | 600-800 | 320*160 | 1/64Scan |

| P1.839mm | 1515 (Black LED) | 174*87 | SMD 3in1 | 600-800 | 320*160 | 1/58Scan |

| P1.86mm | 1515 (Black LED) | 172*86 | SMD 3in1 | 600-800 | 320*160 | 1/43Scan |

| P2mm | 1515 (Black LED) | 160*80 | SMD 3in1 | 600-800 | 320*160 | 1/40Scan |

| P2.5mm | 2121 (Black LED) | 128*64 | SMD 3in1 | 800-1000 | 320*160 | 1/32Scan |

| P3.076mm | 2121 (Black LED) | 104*52 | SMD 3in1 | 800-1000 | 320*160 | 1/26Scan |

| P4mm | 2121 (Black LED) | 80*40 | SMD 3in1 | 800-1000 | 320*160 | 1/20Scan |

| P5mm | 2121 (Black LED) | 64*32 | SMD 3in1 | 800-1000 | 320*160 | 1/16Scan |

250X250mm Series

| Pixel Pitch | LED | Module Resolution | LED Type | Brightness(Nits) | Module Size(MM) | Driving Mode |

| P1.953mm | 1515 (Black LED) | 128*128 | SMD 3in1 | 800-1000 | 250*250 | 1/32Scan |

| P2.604mm | 1515 (Black LED) | 96*96 | SMD 3in1 | 800-1000 | 250*250 | 1/32Scan |

| P2.976mm | 2121 (Black LED) | 84*84 | SMD 3in1 | 800-1000 | 250*250 | 1/16Scan |

| P3.91mm | 2121 (Black LED) | 64*64 | SMD 3in1 | 800-1000 | 250*250 | 1/16Scan |

| P4.81mm | 2121 (Black LED) | 52*52 | SMD 3in1 | 800-1000 | 250*250 | 1/13Scan |

240x240mm Series Indoor LED Display Panel

| Pixel Pitch | LED | Module Resolution | LED Type | Brightness(Nits) | Module Size(MM) | Driving Mode |

| P1.875mm | 1515 (Black LED) | 128*128 | SMD 3in1 | 800-1000 | 240*240 | 1/32Scan |

| P2.5mm | 2121 (Black LED) | 96*96 | SMD 3in1 | 800-1000 | 240*240 | 1/32Scan |

LED Display Module Production: A Comprehensive Guide to Manufacturing Excellence

The LED display market will reach , showing remarkable growth in this technology sector. LED screen module manufacturing has grown beyond basic assembly lines into smart production facilities. Quality LED displays need precision, expertise, and state-of-the-art manufacturing processes.$38.96 billion by 2028

Our years as LED module manufacturers have shown us the most important changes in production technologies and quality standards. This piece explores everything in LED screen module production, from core components to advanced manufacturing techniques. LED display manufacturers who want to improve operations and business professionals who want to learn about commercial LED displays will find detailed insights about manufacturing excellence here.

The analysis dives deep into automated production systems, quality control protocols, and new trends that have altered the map of LED manufacturing. We’ll get into the key factors that help production quality, streamline processes, and create economical solutions in modern LED module manufacturing.

1. Understanding LED Module Components

Let’s look at LED screen module production by exploring the essential parts that are the foundations of every LED display. Our experience as manufacturers shows that the quality of these core elements affects the final product’s performance and reliability.

Core Components and Materials

Every LED display module contains a sophisticated arrangement of components. The basic building blocks include LED chips, PCB board, and integrated circuits. We use semiconductor materials like to construct LED chips. A PCB provides both mechanical support and electrical connectivity, and it typically includes high-grade copper foil that ensures optimal conductivity.

PCB Design Requirements

PCB design plays a vital role in module performance throughout our manufacturing process. The PCB layout needs LED installing holes with precise for depth. Our designs include:tolerances of ±0.05mm

- Thermal management systems with copper planes for heat dissipation

- Sufficient space between margin pads and outer margins

- Copper define on pads to prevent solder mask peeling

Outdoor LED modules need specialized thermal management techniques because these units require brightness levels above 3000 cd/m².

LED Chip Selection Criteria

We select LED chips based on strict criteria to ensure optimal performance. Our team reviews several key parameters:

- Reliability Metrics:

- Failure rate must not exceed three ten-thousandths during the original 72-hour aging period

- Antistatic capability with minimum 2000V human body electrostatic test tolerance

- Performance Parameters:

- Indoor modules: Minimum brightness of 800cd/m²

- Outdoor modules: Minimum brightness of 3000cd/m²

- White balance ratio of 1:4.6:0.16 for red, green, and blue

LED display surfaces must maintain a flatness tolerance of 0 ≤ a ≤ 1mm to prevent image distortion. Our team monitors these specifications carefully during manufacturing to ensure consistent quality in all LED screen modules.

Over the last several years of LED module manufacturing, we’ve learned that strict control over component specifications ensures high-quality LED displays for both indoor and outdoor applications.

2. Advanced Manufacturing Technologies

Our manufacturing facilities feature advanced automation technologies that ensure precision and consistent LED screen module production. Quality and efficiency are the life-blood of our advanced manufacturing capabilities.

Automated SMT Production Lines

High-performance placement machines process in our facilities. These machines enable quick and precise assembly of LED modules. The production lines feature:up to 72,000 components per hour

- Fully automatic solder paste printing with Hawk-Eye paste inspection

- Advanced component scanning and tracking systems

- VXC2450 air soldering systems with multiple independent process zones

- Integrated quality control mechanisms

Precision Component Placement Systems

Precise component placement technologies form the foundation of our manufacturing excellence. The represent the most advanced placement technology in the market. LED components receive specialized handling through optimized pick and place systems with custom nozzle configurations and feeder units.ASM SIPLACE Di2 and TX2 placement machines

A sophisticated tracking system monitors each component’s placement on every board. This ensures complete traceability throughout production. The precision helps maintain consistent quality in all LED screen modules.

Smart Manufacturing Integration

Our production embraces Industry 4.0 principles through expandable smart manufacturing solutions. The intelligent production lines include:

- Up-to-the-minute Data Collection

- Equipment performance monitoring

- Automated quality control systems

- Production metrics tracking and analysis

- Advanced Control Systems

- IoT-enabled device communication

- Automated demand response capabilities

- Intelligent production scheduling

Sensors in our smart manufacturing systems enable adaptive production processes and monitor component placement accuracy and environmental conditions. Intelligent systems exploit IoT capabilities through M2M (Machine-to-Machine) devices and IT automation to improve production efficiency.

Automated optical inspection (AOI) systems detect and eliminate production errors accurately. The 3D AOI system identifies missing components, incorrect placements, and slight misalignments. This ensures every LED module meets our strict quality standards.

3.Production Process Optimization

We go beyond simple automation to deliver excellence in LED screen module production through detailed process optimization. Years of experience have helped us develop sophisticated ways to streamline operations without compromising quality standards.

Lean Manufacturing Implementation

Our LED module production has changed through lean manufacturing principles that focus on efficiency and waste elimination. Each day starts with a 30-minute process improvement session. Our team members, from assemblers to engineers, work together to identify and solve production challenges. This method works well – we value and apply even to boost long-term efficiency.two-second time savings

Our lean implementation success comes from:

- Cellular workstation layouts replacing linear assembly

- Immediate production tracking systems

- Employee-driven improvement initiatives

- Standardized work procedures

- Visual management systems

Production Line Efficiency

Cellular manufacturing has substantially cut move time and queue time in LED module production. ColdLED technology now combines advanced techniques like flip-chip methods and common cathode technology. This results in better production efficiency and thermal performance.

Our production line works better through:

- Smart component placement systems

- Automated quality verification

- Immediate production monitoring

- Integrated testing protocols

- Advanced thermal management systems

Our power supplies reach , which beats the usual range of 85-88%. This helps save energy and improves product performance.92% efficiency

Waste Reduction Strategies

Detailed waste reduction strategies run throughout our manufacturing operations. We work with specialized waste solution providers to meet environmental goals. Careful analysis helps us build systems that cut waste while keeping product quality high.

Energy conservation remains crucial. Better circuit designs and control systems reduce energy loss. Our heat dissipation design uses less energy and produces less heat. Modular designs make maintenance quicker and reduce material waste because we can replace or upgrade individual components.

Our supply chain management includes partnerships that help combine and recycle even small amounts of waste. This systematic approach to waste management reduces our environmental impact and saves money in LED screen module production.

4. Testing and Validation Methods

Quality testing and validation are the foundations of our LED screen module manufacturing process. We use advanced methods to ensure our products are reliable and perform exceptionally well. Our complete testing combines stress testing, performance checks, and reliability measurements to create top-tier LED display solutions.

Environmental Stress Testing

Our LED screen modules go through tough environmental testing that mirrors real-life conditions. The temperature-controlled testing environment runs for long periods. Our advanced testing facilities perform:between 45°C-55°C

- High and low temperature effect tests

- Humidity cycle testing at 90% relative humidity

- Salt spray and dust resistance checks

- Vibration and impact resistance verification

- Solar radiation simulation tests

These environmental tests help us spot weak points and make sure our LED displays work perfectly in a variety of operating conditions.

Performance Validation Protocols

The performance validation runs aging tests from 24 to 72 hours. We watch several parameters closely to check module functionality. Our validation has brightness testing requirements – outdoor modules must stay above 1200cd/㎡-2000cd/㎡.

Our well-laid-out validation process has:

- Original parameter checks and baseline testing

- Ongoing monitoring during aging cycles

- Color uniformity and balance measurements

- Dead point inspection and analysis

- Module flatness checks within ±0.1mm tolerance

Reliability Assessment

Our reliability checks use advanced accelerated stress testing (AST) to measure long-term performance. The moisture-electrical-temperature (MET) test framework has cut validation time from 6000 hours to 100 hours. This breakthrough lets us keep high quality standards while meeting market needs quickly.

Advanced Life Testing (ALT) protocols with accelerated thermal tests and stress calculations guarantee industry-leading reliability. The testing looks at functional lifetime across many performance parameters and measures how things break down in different environments.

Our complete reliability program has created sophisticated validation methods that check LED performance at the module level. Products consistently hit their predicted lifetime marks. This testing spots potential building block failures just 400 hours into testing, so we can fix issues before they affect product performance in actual use.

5. Industry Standards Compliance

Quality and safety standards are the foundations of our LED screen module manufacturing process. We are a leading LED module manufacturer who knows that global certifications will give a clear measure of product quality and safety worldwide.

International Manufacturing Standards

Our LED display manufacturing follows multiple international standards. The ISO9001 quality management systems certify our production facilities to deliver consistent quality in all our LED panel modules. We follow IEC 62031:2018 standards for electrical safety and performance. These standards give complete requirements for LED modules that operate under different voltage conditions.

Our manufacturing processes have:

- Performance Standards: IEC 62717:2014 requirements for LED module performance

- Safety Protocols: UL 8750 standards for LED equipment safety

- Environmental Guidelines: RoHS certification for hazardous substance restrictions

- EMC Requirements: IEC/EN61547 for electromagnetic compatibility

Certification Requirements

Our LED screen modules meet global market needs through detailed certification documentation. Regular factory inspections and safety-critical component monitoring are essential. Here’s what our certification process covers:

- Technical Analysis Phase

- Product design evaluation

- Material composition verification

- Safety feature assessment

- Testing Requirements

- Electromagnetic compatibility testing

- Environmental stress evaluation

- Performance validation protocols

Quality systems are a big part of what we do. We check incoming goods, document materials, and verify final products thoroughly. Regular updates to our calibration procedures help us maintain valid certifications for measuring and monitoring equipment.

Regulatory Compliance

Each market has its own certification needs. Our LED display products meet every regional requirement. The European market requires CE certification to cover essential health and safety standards. Our products in North America comply with UL and FCC standards, with special focus on electromagnetic radiation limits.

Regional compliance has:

- North America: UL, ETL, FCC certifications

- European Union: CE, RoHS, ENEC marks

- Asia Pacific: CCC, PSE, KC certifications

- Middle East: SABER certification

Manufacturing processes need careful monitoring because certification can be withdrawn if unauthorized changes occur. Our steadfast dedication to regulatory compliance extends to environmental sustainability. LED panel display modules meet energy efficiency requirements in different regions.

We keep a close eye on changes in international standards and update our manufacturing processes. This helps our commercial LED displays exceed global regulatory requirements consistently. Quality standards in LED screen module production remain our top priority.

6.Troubleshooting and Quality Assurance

Our experience as LED module manufacturers has taught us that quality assurance and troubleshooting are crucial to production excellence. We have created detailed systems to handle common issues and maintain consistent quality in LED screen module production over the last several years.

Common Production Issues

Our LED display manufacturing experience reveals several recurring challenges that need immediate attention. Our data shows that receiving card malfunctions can affect all but one section of LED displays. Power supply failures and module brightness inconsistencies rank among the most frequent problems we need to solve.

The core team regularly handles these production challenges:

- Color disparity between modules

- Connectivity failures in panel networks

- Inconsistent brightness levels

- Signal processing issues

Our extensive testing protocols show that LED modules need a 24-hour aging test while assembled cabinets require a 72-hour test. These measures reduce post-production issues substantially.

Problem Resolution Protocols

We follow systematic troubleshooting approaches that quickly identify and resolve problems. Our detailed inspection protocol looks at:

- Power Systems: The team verifies power connections and voltage levels before moving to complex diagnostics

- Signal Processing: We check communication pathways and controller functionality

- Module Performance: Module-level testing helps isolate specific issues

Quality assurance demands dust-free production environments and precision instruments to boost manufacturing reliability. Our testing procedures have comprehensive brightness verification, and outdoor modules must maintain specific luminance levels.

Quality Control Metrics

Our quality control system follows strict standards throughout all production phases. The acceptable quality level (AQL) stands at three percent, meeting the industry’s highest standards. Our quality metrics include:

Production Testing Parameters:

- 72-hour aging period with failure rates below three ten-thousandths

- Minimum 2000V human body electrostatic test tolerance

- Temperature-controlled testing environments (45°C-55°C)

The building block release system we use allows reliability teams to work from multiple locations. They test an average of 3,000 LED modules simultaneously. This approach helps identify potential failures early in the production cycle.

Our integrated quality management system keeps detailed records of all testing procedures and results. The quality inspection process verifies:

- Raw material specifications

- Component placement accuracy

- Soldering quality

- Visual performance parameters

Strict control over these metrics and systematic problem-resolution protocols help streamline processes while maintaining exceptional quality standards. Our steadfast dedication to excellence shows in our detailed testing procedures. We conduct thorough lighting tests and extended aging periods to ensure optimal performance under various conditions.

7. Future Manufacturing Trends

The manufacturing technologies in LED screen module production are changing rapidly. These changes will revolutionize our industry. Traditional manufacturing now combines with advanced technologies to create better production efficiency and quality control.

AI and Machine Learning Integration

Our LED manufacturing operations now use sophisticated AI and machine learning systems. Data shows that machine learning algorithms can substantially improve production efficiency by analyzing big amounts of real-time manufacturing data. Our advanced AI systems have achieved notable improvements in:

- Predictive maintenance capabilities

- Real-time quality control optimization

- Production line efficiency monitoring

- Supply chain management

- Automated decision-making processes

Machine learning helps us analyze supplier data better. We can now select suppliers based on location, costs, past performance, and reputation. AI-powered frameworks cut down time-to-market while making products better with more customization options.

Industry 4.0 Applications

Industry 4.0 principles have changed our LED screen module production through industrial internet of things (IIoT). Physical manufacturing now combines with big data and artificial intelligence to create continuous information flow that mirrors ground products and processes. Our teams can now:

- Monitor production metrics in real-time

- Optimize manufacturing processes automatically

- Implement predictive maintenance protocols

- Accelerate time to market

- Enhance supply chain visibility

Smart factory technologies help us achieve higher output while keeping quality standards consistent. IoT integration enables remote control, intelligent diagnosis systems, and content cloud updating features for LED displays.

Sustainable Production Methods

Our LED screen module production focuses on environmentally responsible manufacturing. Technology helps us improve energy efficiency while using fewer raw materials per unit.

Environmental awareness shapes our manufacturing decisions. We have created complete waste recycling and processing systems that meet strict environmental requirements. Our environmentally responsible approach includes:

- Using eco-friendly materials and green production processes

- Applying energy-efficient manufacturing techniques

- Using recyclable components like aluminum frames

- Creating products with longer lifespans to reduce electronic waste

Advanced manufacturing systems have improved energy efficiency substantially. Our latest LED displays perform better while using less power. We train employees in environmental awareness to create shared responsibility.

Digital twins let us simulate operations and test changes virtually before actual implementation. This technology helps optimize production processes and minimize waste. Data analytics gives us real-time information about production efficiency. We can make better decisions about resource allocation and process optimization.

Our heavy investment in research and development strengthens technological capabilities. This investment will give a competitive price while maintaining high quality standards in LED screen module production. Our R&D team creates customized LED display solutions that meet specific project requirements and follow environmentally responsible practices.

These improvements reshape LED screen module production’s future. AI-driven automation, Industry 4.0 integration, and environmentally responsible practices make us a leading manufacturing innovator. We stand ready to meet the global LED display market’s changing needs.

8. Conclusion

LED screen module manufacturing combines precision engineering with innovative technology. This piece explores everything in producing high-quality LED displays. We cover basic components and innovative manufacturing techniques that matter.

Automated SMT production lines work alongside advanced quality control systems and strict testing protocols to deliver exceptional product quality. Modern LED manufacturing requires strict compliance with international standards. The production methods need to be quick and eco-friendly.

Smart manufacturing shapes the future of LED screen module production. AI and machine learning transform traditional processes continuously. Our industry grows through eco-friendly practices and improved energy efficiency. New production methods reduce waste and maximize quality.

Our manufacturing experience spans several years. We learned that LED module production success depends on adapting to new technologies. Quality standards remain steadfast. This perfect mix of innovation and reliability helps our LED displays meet today’s market needs and tomorrow’s technological challenges.

9. FAQs

Q1. What are the key components of an LED screen module? An LED screen module typically consists of LED chips, a driver circuit, and a heat sink. The LED chips produce light, while the driver circuit regulates current and voltage to ensure optimal performance. The heat sink helps dissipate thermal energy, maintaining the module’s efficiency and longevity.

Q2. How are LED screen modules manufactured? LED screen module manufacturing involves several steps, including technical study, structural design, assembly of components, and tuning. The process utilizes automated SMT production lines for precise component placement, followed by rigorous quality control and testing procedures to ensure high-quality output.

Q3. What materials are commonly used in LED screen production? LED screens primarily use aluminum gallium indium phosphide alloys for red, orange, and yellow light, and indium gallium nitride alloys for green, blue, and white light. Other materials include circuit boards, heat sinks, and protective casings, often made from aluminum or other durable materials.

Q4. How is quality control maintained in LED module production? Quality control in LED module production involves automated optical inspection (AOI) systems, electrical parameter testing, and environmental stress testing. Manufacturers implement strict quality assurance protocols, including pre-production material verification, in-line quality checks, and post-production testing to ensure consistent performance and reliability.

Q5. What are the future trends in LED screen module manufacturing? Future trends in LED screen module manufacturing include the integration of AI and machine learning for process optimization, implementation of Industry 4.0 principles for smart manufacturing, and a focus on sustainable production methods. These advancements aim to improve efficiency, reduce waste, and enhance product customization while maintaining high-quality standards.